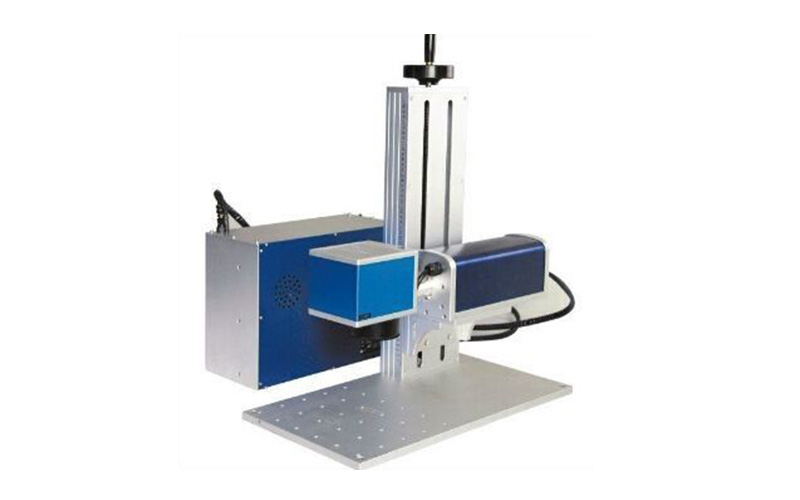

| Product Details | |

| Place of Origin: | China |

| Brand Name: | Fiber Laser |

| Certification: | CE |

| Model Number: | LB-MF |

| Detailed Product Description | |||

| Model: | LB-MF | Wavelength: | 1064nm |

| Speed: | ≤8000mm/s | Min Liner Width: | 0.01mm |

| Beam Quality: | M2≤1.8 | Control System: | EzCad.2.10.1 |

| Laser: | Fiber Laser | Min Characters: | 0.15mm |

| Power Supply: | AC220V/50Hz | Working Area: | 50x50mm-300x300mm |

| Dimension: | 800x680x700mm | ||

Standard Accessories

A semiconductor module

A set of high-speed vibrating mirrors

A set of marking control system

A set of laser marking sysytem

An industrial computer

A marking work table

A red laser pointer

A pedal switch

A set of marking software

A "Instruction Book", "Operation Manual" and "Training Video”

| Technical parameters | |||

| Type | LB-MF10 | LB-MF20 | LB-MF30 |

| Power | 10W | 20W | 30W |

| Beam quality | M2≤1.4 | M2≤1.8 | M2≤1.8 |

| Marking speed | ≤7000mm/s | ≤8000mm/s | ≤8000mm/s |

| Power consumption | 0.5KW | 0.8KW | 1.2KW |

| Fiber Laser | AO Q-Switch Pulse Fiber Laser | ||

| Wavelength | 1064nm | ||

| Laser marking software | EzCad.2.1 | ||

| Working area | 50x50mm-300x300mm | ||

| Minimum Linewidth | 0.01mm | ||

| Repeated precision | ±0.001mm | ||

| Min characters | 0.15mm | ||

| Cooling system | air-cooling | ||

| Location System | Red dot indicater | ||

| Power supply | AC220V/50Hz | ||

| Control System | Ezcad Motion Control Card-PC | ||

Dynamic Focusing device | Yes | ||

| Dimension | 800x680x1200mm | ||

a. Using the third generation of optical fiber solid laser, the electro-optical onversion ecfficiency of pump light source can reach to 80% after fiber coupling. Higher beam quality, long use time, laser life can reach 100000 hours(Lamp pump YAG is around hundreds of hours, semiconductor is around 10000 hours).

b. Perfect beam quality achieved the highest and excellent marking effect. And it has great advantages of doing anti-white,matte,chromatic...on the stainless steel.

c. Adopted imported high-speed scanning head, and combined with software makes engraving very fast, so the processing speed is 3 to 5 times quicker than the ordinary YAG and DP semiconductor.

d. Air-cooling, no consumables, free maintenance, save power and energy(total power is 500W), low cost of latter usage, the annual electric savings would be around USD3000-5000.

g. Integrated modularization design, convenient maintenance, and the small volume can save more space.

e. High electrooptical efficiency: integrated electooptical efficiency reaches above 20%, greatly saved power consumption and operation cost.

f. Absolutely environmental marks without intermediate mediators involved in processing, completely in conformity with ROHS Standards.

h. Support JPG, PNG, BMP, PLT, DST, DXF, CDR, AI, DSB, GIF, MNG, TIF, TGA, PCX, JP2, JPC, PGX, RAS, PNM, SKA, RAW and other documents, and can form the serial number,production date, bar code and QR code automatically.

i. Optional rotary workable and other automated matching system.

Our Service

Spot delivery, including delivering small batches of goods

Provide wide-range and complete materials series products

Cutting plates, including complex shapes of materials and special processing and disposal

Cutting bars and strips

Our application technology expert provide the best material and recommendation

One-stop service